For over 50 years, OSRAM HMI lamps have been meeting the toughest demands of the film and TV industry. HMI lamps simulate a daylight colour temperature of 6000K and have excellent colour rendering and photometric integrity throughout their life.

OSRAM received an OSCAR® in 1987 and a PRIMETIME EMMY® Engineering award in 2007 for the invention and continuous improvement of HMI lamp technology. As a result, the HMI lamp family continues to be an integral part of film sets around the world.

However, another one of the major applications of OSRAM HMI® 4000 W/DXS is in solar simulation, specifically in automotive testing laboratories. Solar radiation causes numerous unwanted effects on materials exposed for extended periods. These changes range from aesthetics (like fading colours) to structural changes (increase in brittleness and the loss of various strengths).

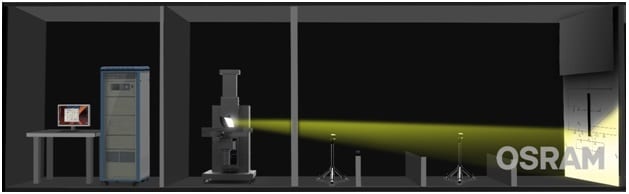

Solar simulation testing is used to simulate the spectra of natural sunlight to help determine how a material will react when exposed to sunlight over a period of time. A solar simulator is also known as an artificial sun as it is a device that provides illumination which is as close to the natural light as possible.

The purpose of the solar simulator is to provide a controllable indoor test facility under laboratory conditions, used for the testing of solar cells, sunscreen, plastics, and other materials and devices.

The OSRAM HMI® 4000 W/DXS SOLAR is a double-ended metal halide lamp. Its funnel-shaped burner is specially designed for super quiet operation on electronic power supplies which acts as a major support base when we talk about solar Simulation.

The HMI® 4000 W/DXS SOLAR can be operated either on magnetic ballast (CCG) or on electronic power supplies (ECG). For best performance, we recommend the use of an ECG. Magnetic ballasts can reduce lamp performance and hence, caution is of the best priority in these cases especially when it concerns the Automotive Testing Laboratory or a car manufacturing factory.

- Lamp wattage: 4000 W

- Nominal voltage: 204 V

- Lamp voltage: 200 V

- Nominal current: 23.5 A

- Lamp current: 24.0 A

- Colour temperature: 6000 K

- CRI › 90

- Lifespan: 500 h

- Base (standard designation): SFa21-12

Luminous flux, CRI and CCT may vary during lifetime. Their behaviour strongly depends on the switching cycle applied for lamp operation. In general, a decrease in luminous flux and CCT can be expected.

OSRAM HMI® lamp is a product category containing the latest technology and know-how in this segment.

Whether it’s a car manufacturing factory or an Automotive Testing Laboratory- the indispensable characteristic of such highly developed products that they are sensitive to all kinds of external influences. The functionality of the individual features of our products is influenced by various external factors and may therefore differ depending on the individual application or condition of use.

It is up to the user to make his own determination as to the suitability of a lamp for his intended application or use and to assume responsibility for that determination.

Boosting of metal halide lamps: Operating the lamp at higher than the rated lamp wattage is not allowed. Besides affecting the photometric properties of the lamp (higher CRI, lower CCT) the increased load on the electrode system, sealing and the bulb will lead to a premature failure of the lamp while being used in an automotive Testing Laboratory or even a car manufacturing factory which can result in hazardous problems.

Light output:

Test conditions: 4000W operation > 6 min for lamp output stabilization

Lamp driver:May&Christe HMI 4000W-05,2H

Luminous flux: Light output of the lamp is measured within an integrating sphere (diameter 2000 mm).

- I) Initial values

Min.: 330.000 lm

Typical: 398.000 lm

- II) After average service life (500 h)

Min.: 50% of the initial value (B50)

Color coordinates: I) Initial values

Typical x: 0,308

Typical y: 0,313

CRI:I) Initial values

Ra typical > 90

Correlated Color Temperature2 I) Initial values

Typical: 7000 (+400 / -400) K

Luminous flux, CRI and CCT may vary during lifetime. Their behaviour strongly depends on the switching cycle applied for lamp operation. In general, a decrease in luminous flux and CCT can be expected.

Average lamp life and lumen maintenance:

Switching cycle 210 min. on, 30 min. off

Lamp life time5: 500 h typical @ 4000 W

More than 50% of the lamp population have light output > 50% of the initial min. lumen output at lamp lifetime. The light output of the lamp is measured within an integrating sphere (diameter 2000 mm).

Safety recommended during use:

Mainly Because of their high luminance, UV radiation and high internal pressure during operation, HMI lamps may only be operated in enclosed lamp casings specially constructed for the purpose.

Appropriate filters must ensure that UV radiation is reduced to an acceptable level. Mercury is released if the lamp breaks. Special safety precautions must be taken. Information on safety and handling is available on request or can be found in the leaflet included with the lamp or in the operating instructions.

Comment on this article